The jaw plate is a most important component in the jaw crusher machine and also its life of solution is straight affecting the complete jaw crusher device. Therefore, you ought to take into consideration the durability along with firmness of a jaw plate, when you actually require to pick the right one. If a sturdiness of jaw plate is greater, the infiltration of material pushed right into a jaw plate will be little that can quit the surface area from distortion as well as also lessen the upsetting output caused by a coming down of the unpleasant. Besides that, the material of jaw plate must have a details hardness that can stop the problems of broken or harmed throughout the process of extrusion and likewise assure the typical use of jaw plates

Significant reasons for the wear of jaw plates.

There are leading factors for the wear of jaw plates that consist of:

The product slides for a substantial time at the launch port

For double clip jaw crusher plate, the grade of its upright swipe is more than that of straight swipe. The higher the vertical swipe, the substantial the ore slides, so the wear of jaw plate especially a portion near the launch port is extra thoughtful.

Additionally, the wear of moulding is greater than that of extrusion that constructs a lesser component of the jaw plate uses quicker than it's a greater part. In order to optimize its life of solution, individuals need to always shot a lower jaw plate benefit to make both the sides constricted regularly.

Large quantity of penalties in the product

The wear of jaw plate is fully based on the sort of your material along with various other variables like material dimensions. Even way too much of fines enter into the dental caries of jaw crusher and it will certainly quicken the jaw plates, because the fines will certainly stops the valleys that are necessary for a crusher to push them better.

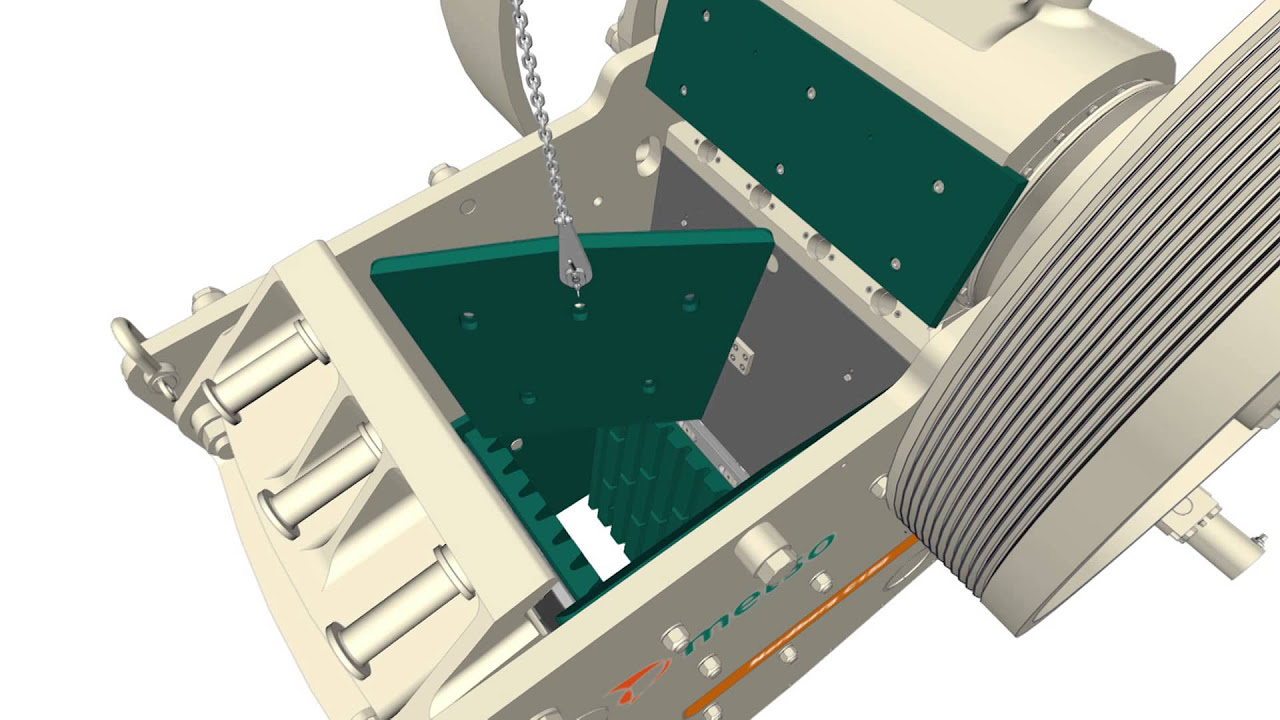

Typically, the jaw crusher completes a procedure of crushing by simply pressing the product between the moving along qimingcasting.com with stationary jaw plates. Likewise, the valleys and peaks of jaw plates are counterbalance from each other and likewise make use of the automated benefits of influence to disrupt a rock.

Without using this, the crusher needs to depend upon resistance as well as power to push the rock. Also, its compaction will certainly apply enhanced loads on home plates of jaw crusher as long as 5 times the standard squashing pressure.

Huge feeding product dimension

If the product of feeding is massive, it will severely impact the life of a solution. In a number of applications, the lowering ration of jaw crusher is 6:1. Past the decrease ratio will certainly also create the crushing pressures, which would stop the limits of crusher layout as well as likewise impact your total performance of an equipment and also its manufacturing also. For enormous feed material, if you bush a product until home plate of jaw can acquire a morsel over it; this would accelerate the wear also.

Utilizing the dust destruction with water

Making use of the dirt devastation is one more element; due to the fact that the water is really harsher as well as will likewise quicken the wear of plates. The Fote equipment additionally suggests you to utilize the practical spray dust reductions; due to the fact that it can contest the water to grime and thus, connect a higher regulator of even more dust with the less water.

The jaw plate is seriously used that can result in rutted the dimension of a bit in addition to low effectiveness, which specifies that you need to exchange the jaw plates. If you actually need to choose a right one, you should consider their varied materials based upon the actual condition as well as decision too.

What kinds of materials are there for jaw plate?

High manganese steel

The high manganese steel contains reasonably high carbon content that plays a supreme role in the resistance of wear. Generally, the durability improves with the development of carbon material. Beneath the non-strong impact conditions, making the most of the carbon web content is a lot more beneficial to improve the wear resistance of steel That is why; high manganese steel has best distortion setting capacity.

Tool carbon low alloy cast steel.

It is a majorly used for wear immune product. Because of its suitable solidity and also greater durability, it can extremely metso jaw crusher parts withstand the spalling of exhaustion brought on by duplicated extrusion of materials as well as likewise displays the best wear resistance also.